Sistema ERP se convierte en una herramienta de comunicación

Por: Emily Probst

Los módulos de software de planificación de recursos empresariales proporcionaron una comprensión global de la prioridad y la ubicación del trabajo entre los diferentes departamentos cuando las restricciones de la pandemia interrumpieron los entornos de trabajo colaborativo.

#gestion-de-taller-metalmecanico #manufactura-avanzada

Aplicaciones y beneficios del superacabado de partes metálicas

Por: Emily Probst

Descubra qué es el superacabado, en qué aplicaciones se usa y por qué debe tener cuidado al especificar parámetros de acabado superficial.

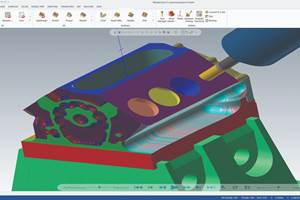

CAM: cómo pasar de programar en máquina a la programación CNC fuera de línea

Por: Emily Probst

En pleno proceso de aprendizaje de la programación de sus fresadoras CNC fuera de línea y con la intención de utilizar esa experiencia para transferir más trabajo a su torno de tipo suizo, un taller de Ohio cambia su cultura de empresa y asume trabajos más complejos.

Taller de mecanizado automatiza producción con brazo cobot

Por: Emily Probst

Cargar y descargar un trabajo repetitivo extenuaba a los empleados de B.I.C. Precision Machine, por lo que el taller integró un brazo cobot de Absolute Machine Tools en su proceso de producción

Estudiantes de mecanizado CNC cuentan ahora con software CAM intuitivo

Por: Emily Probst

Un instructor de mecanizado de Lincoln College of Technology detalla las funcionalidades más útiles del Mastercam, el software que eligió para su escuela.

Fresadora CNC de pórtico que proporciona años de operación suave

Editado por Emily Probst

Neuman & Esser utiliza su fresadora CNC Droop+Rein, de Starrag, con ocho años de antigüedad, como un “caballo de batalla” para el mecanizado completo.

Avances en acabado abrasivo para máquinas CNC

Editado por Emily Probst

Conozca cómo las herramientas de acabado abrasivo pueden mejorar la eficiencia y la precisión de las operaciones CNC sin liberar partículas dañinas.

Perillas de retención de alto torque resuelven el producción de fresado aeroespacial

Editado por Emily Probst

L.H. Thomson utiliza las perillas de retención de alto torque de JM Performance Products en todas las herramientas de sus máquinas para mejorar las operaciones de fresado pesado en piezas de titanio y acero inoxidable.

#caso-de-exito

Estandarización de la marca Mazak facilita el proceso de capacitación de un taller

Editado por Emily Probst

La elección de una única marca de máquinas-herramienta les ha permitido a los operadores de Ketchie Inc. ser autosuficientes. Pueden aprender rápidamente a configurar y programar casi cualquier máquina del taller.

#caso-de-exito

Máquinas-herramienta de gran tamaño son impulsadas por nuevo CNC

Editado por Emily Probst

Con el propósito de complementar las fortalezas de muchas de sus máquinas-herramienta más grandes, Tarus ha añadido un CNC de Heidenhain para beneficiar a los fabricantes que buscan capacidades de fresado de superficie de contorno de alta calidad.

#caso-de-exito

Ponga a trabajar a sus operarios en la manufactura de matrices

Por: Emily Probst

Al sistematizar la fabricación de matrices en pasos repetibles, Dies Plus, está empleando a sus operarios de máquina para hacer troqueles de manera efectiva. Esta solución se basa en un sistema de codificación de colores sin papel para transmitir las tolerancias que los operarios deben alcanzar para que los fabricantes de herramentales y matrices realicen el ajuste final.

Proceso de control de calidad mejorado con recopilación de datos y análisis en tiempo real

Por: Emily Probst

Pinnacle Machine Works utiliza el software de recopilación de datos y SPC MeasurLink, de Mitutoyo, para hacer que el proceso de control de calidad sea más eficiente y preciso.

#caso-de-exito