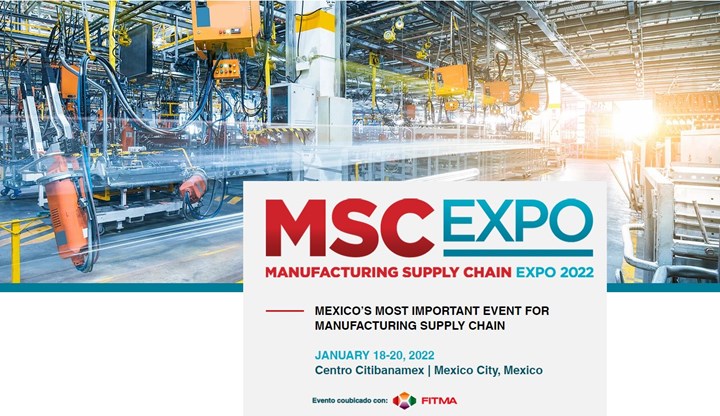

MSC Expo: the commitment to a supply chain that generates value for companies

Eduardo Medrano, president of the AMMMT and president of ISTMA Americas, says that in the current context MSC Expo is a key event for the supply chain to generate value for companies in Mexico and the region.

#fitma

In a context where the dynamics of business interaction has changed permanently, MSC Expo becomes a key event for the supply chain in Mexico and the region, is the initial reflection of Eduardo Medrano, president of the Mexican Association of Mold and Die Manufacturing (AMMMT) and interim president of ISTMA Americas.

Medrano says that MSC Expo, which will be held from January 18 to 20, 2022 at the Citibanamex Center in Mexico City, is an innovative, large-scale exhibition that did not exist in Mexico or anywhere else in the world.

“We are going to have companies hungry to find customers and what better than to give ourselves this projection through an international exhibition in which all of us who manufacture can unite and reach in a very different −and I would say innovative− way the auto parts, machining, maquiladora and other industries,” Medrano says.

Opportunities for the Supply Chain

According to Eduardo Medrano, at MSC Expo companies have the possibility of capturing all the opportunities offered by the market since the T-MEC, after the difficulties experienced last year and the relocation that is on the horizon: "It is time to position our brands, to be in the minds of manufacturing consumers and that we can efficiently leverage commercial efforts".

He points out that since this is the first edition, and above all in a cross-cutting and crucial issue of the supply chain in the continent, it is key to attend MSC Expo with the intention of opening the horizon and asking, what else is there?

“Usually, customers work with the suppliers that come to their factories and with the suppliers that are contacted; but when you get to this type of exhibition you will get to see more than what you typically see. Above all, you start to see new applications, new manufacturing processes, companies that are innovating within the new product markets,” Medrano says.

He explains that it is not only about supply, but also about the implementation of the latest technology through suppliers: “What are our suppliers today in terms of manufacturing trends, what are they using for design, what are they using for machinery, how are they facing the challenges of health, and how are they facing the issue of competitiveness and local productivity in Mexico and regionally in the Americas?”

Medrano points out that one must come to MSC Expo with a willingness to be open to the horizon of meeting more than 100 manufacturing suppliers to identify what technologies and what opportunities there are to enrich their own companies: “Sometimes we stay with processes or with suppliers of decades and we fail to explore other technologies through suppliers that can make our company more profitable or even differentiate it”.

Medrano says that we must also be willing, in a certain way, to unlearn: “There is an author called Barry O'Reilly, who talks precisely that this pandemic, this health situation and global crisis, is leading us not only to learn how to do things, but to unlearn how things are done. This unlearning is that we have to erase certain models and paradigms of how the industry was managed and reach a new dynamic, where through hybrid efforts and, particularly, talking person to person, we can in a few days meet more than 100 manufacturing companies”.

And I would ask one question - Medrano pointed out - how many of the decision makers, directors or purchasing areas could see more than 100 suppliers in a few days?

“I would say that sometimes it takes years before they can do that. MSC Expo provides that opportunity but, it's true, you have to change your attitude and unlearn how we do things and now come to learn a new dynamic, open that horizon with more than 100 suppliers. We are going to be surprised that many of the productive capacities of these supplier companies are going to be used in some way. Even if we do not use them today, it will open the perspective to know how we can use them and how we can add value in differentiated manufacturing,” he says.

CONTENIDO RELACIONADO

-

El sistema EOS M 290 ofrece impresión fiable

FITMA: EOS (stand 2042) presentará en la feria el sistema EOS M290 de impresión 3D.

-

América Latina frente a la transformación digital

En el contexto de la transformación digital en América Latina, FITMA apuesta por conectar la cadena de proveeduría de manufactura global con el rápido crecimiento del mercado industrial de América Latina.

-

FITMA: el lugar para estar y ser visto en Latinoamérica

Claude Mas, director ejecutivo de Negocios Internacionales en Gardner Business Media, comparte sus impresiones sobre la Feria Internacional de Tecnología y Manufactura (FITMA), que se llevará a cabo en Ciudad de México del 18 al 20 de enero de 2022.